Info

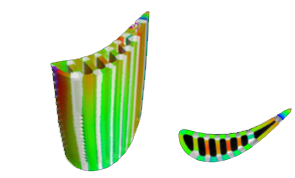

Our engineers, in collaboration with our Partners, use the best manufacturing and repair technologies to refurbish gas turbine (both land-based industrial and civil aviation machines) parts specially hot parts including blades, vanes, hot segments, honeycombs etc. in this regard, we offer the following services to our customers:

- Repair facilities are:

- Stripping (Blasting or chemical stripping)

- Blending

- Brazing

- Grinding

- Laser drilling

- Coating

- Welding (laser or TIG)

- Hot isostatic pressing (HIP)

- Heat treatment

- Metal and ceramic (TBC) coating using below technologies:

- Atmospheric plasma spray (APS)

- High velocity oxy fuel (HVOF)

- Vacuum plasma spray (VPS)

- Pack aluminizing

- During the whole manufacturing process, starting from the raw material, all individual parts are monitored and inspected using below quality facilities:

- Dimensional check

- Eddy current test (ECT)

- Flow measurement (air flow test or water flow test)

- Fluorescent penetrant test (FPT)

- Frequency test

- Optical microscope

- Scanning electronic microscope (SEM)

- Tensile test

- Wall thickness measurement

- Ultrasonic test

- X-ray

- Faro edge scan arm HD

- CMM machine

- Tomography

- Heat tint test

Category

services